Comparison of dipping process and injection process

Date of issue:2020-12-26

Many protective plastic products can be processed by dipping equipment and injection molding equipment. Both processing methods have advantages and disadvantages, and it is difficult for manufacturers to decide which one to use. However, dip molding equipment has many advantages over injection molding equipment. Generally speaking, the use of immersion equipment processing instead of injection molding equipment processing has the following reasons:

Cost: Generally speaking, the processing cost of dipping plastic is very low compared with the processing cost of injection molding. This is mainly due to the cost of dipping processing equipment itself, mold processing costs and the lower cost of materials used for dipping processing.

Shorter mold product design cycle: the processing and production of the mold in the dipping processing equipment is a simple process (reverse design and processing according to the product structure). The process of dipping process is to first immerse the mold into the dipping liquid, and then the dipping liquid hardening. And the injection mold design, production cycle is long, and complex.

Fast design of the structure of various products: for dipping processing, in the product line is very convenient to change the raw materials or design the structure of the product. By dipping the same mold into different dipping solutions, material products of different strength and structure can be quickly prepared to meet the needs of different applications.

Simple, one-step molding: the soaking process is very simple. All dipping equipment only dips the mold into the dipping liquid, and once the dipping liquid has hardened, the product can be formed. There is no auxiliary demoulding, molding and melting device in the production process.

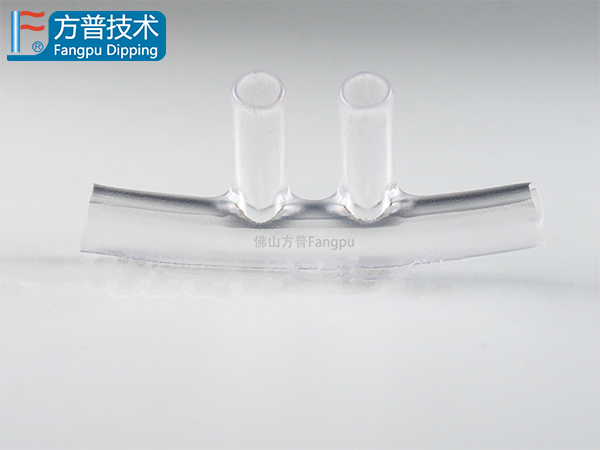

The product does not have the fusion line: the injection mold usually has the fusion line in the mold parting surface position. This fusion line can cause the strength of the product to deteriorate at the junction. The dip-plastic products will not produce fusion lines, and can withstand external forces evenly from all angles of the product, there is no weak strength concentration point.